VFD Drilling Rig

Product explanation:

Cetas can manufacture and provide AC VFD drilling rigs range from 1000 to 12000 meters in drilling depth. Main motors auto-driller and other new advanced technologies have been adopted in the AC VFD drilling rig, both the quantity and technology are in the leading position all of the world. The advantage of AC VFD drilling rig is the AC motor brushless, no spark; stable start, high overload capacity; large speed regulation range with constant power, high system power factor, low motor power; rotary table and draw works are four quadrant running and full digital vector control; feedback/dynamic braking is used to replace auxiliary brake; zero maintenance can be achieved with reliable performance; communication and network is available by using PROFIBUS technology. Auto drilling technology improved the drilling efficiency. So AC VFD drilling rig is the first choice by the domestic and overseas drilling contractor for deep and super deep well.

Product Features:

Adopting advanced full numerical AC VFD technology, intellectual drilling control is accomplished through PLC, touch screen and integrated design of air, electric, hydraulic parts and drilling instrumentation.

Large power and wide frequency motors are used for complete range speed setting of drawworks, rotary table and mud pumps.

Single shaft, gear drive and one or two shift smooth speed change drawworks is simple in structure and reliable in operation. Compound hydraulic disc brake and dynamic braking are used for braking system.

Automatic drilling is obtained by drawworks main motor or an independent motor real time supervision and control for tripping in, tripping out and drilling operation are obtained.

Protective functions to air or hydraulic loss, electric control system or motor trouble, limit for rotary torque and pump pressure is available.

A separate driller cabin is fitted. Operations for air, electric and hydraulic, drilling data and parameters are all in the cabin. Logic control, supervision and maintenance during complete drilling operations are available by PLC processes. The drilling data can be stored, printed and remote transmitted. All operations by driller can be completed in the cabin for better working conditions and less working strength.

Top drive drilling system can be equipped.

Integrated skid rail may be provided to meet requirements for cluster well drilling.

Intellectual soft starting device, ET200 or ASI module is used for protection and supervision to MCC system.

Intellectual position control for traveling block to prevent top and low collision is provided.

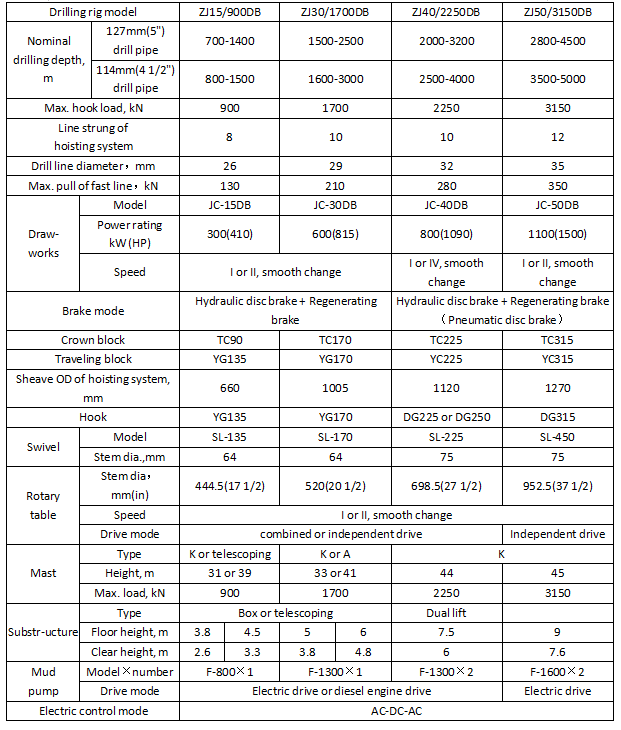

Product types and specifications: